ProductProduct Center

CNC hardware

Aluminum profile

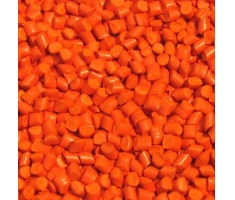

Color Masterbatch

- Filler Masterbatch

- Red Masterbatch

- Green masterbatch

- Blue Masterbatch

- Yellow Masterbatch

- Founctional Masterbatch

pvc resin

Shenzhen Feng Yu Technology Co. Ltd

Phone:+86-13662907063

Email:admin@s-zfengyu.com

Add.:Cao Le Scare Corner Industrial Zone, Xiegang Town, Dongguan City, Guangdong Province, China

Contact:Staven Zeng

Company News

Company News

What is color masterbatch

Colour masterbatch is also known as color seed. Colour masterbatch is a new type of special colorant for polymer materials, also known as Pigment Preparation. It consists of three basic elements: pigments or dyes, carriers and additives. It is an aggregate obtained by uniformly loading super-large amounts of pigments or dyes into resins. It can be called Pigment Concentration, so its dyeing power is higher than that of the pigments themselves. Simply put, masterbatches are aggregates made by uniformly loading supernormal amounts of pigments or dyes into resins.

2. What are the basic components of color masterbatches?

The basic components of color masterbatch are as follows:

1. Pigments or dyes

Pigments are divided into organic pigments and inorganic pigments.

Commonly used organic pigments are: phthalocyanine red, phthalocyanine blue, phthalocyanine green, sunproof bright red, macromolecule red, macromolecule yellow, immortal yellow, immortal purple, azo red, etc.

Commonly used inorganic pigments are: cadmium red, cadmium yellow, titanium dioxide, carbon black, iron oxide red, iron oxide yellow, etc.

2. Carriers

It is the matrix of color masterbatch. Specialized masterbatches generally choose the same resin as the product resin as the carrier, and the compatibility between the two is the best, but the fluidity of the carrier should also be considered.

3. Dispersants

The melting point of dispersant should be lower than that of resin. It has good compatibility with resin and affinity with pigment. The most commonly used dispersants are polyethylene low molecular wax and stearate.

4. Additives

For example, flame retardant, brightening, antimicrobial, antistatic, antioxidant and other varieties, unless the customer requests, in general the masterbatch does not contain the above additives.

3. What varieties and grades are the color masterbatches?

There are several commonly used methods for the classification of chromatic masterbatches:

Classification by carrier: PE, PP, ABS, PVC, EVA, etc.

Classified by use: such as injection colour masterbatch, blow moulding colour masterbatch, spinning colour masterbatch, etc.

Varieties can be classified into different grades, such as:

1. Advanced injection colour masterbatch:

It is used for cosmetic packaging boxes, toys, electrical appliances and other advanced products.

2. Ordinary injection colour masterbatch:

It is used for general daily plastic products, industrial containers, etc.

3. Advanced Blowing Master:

Used for blow moulding and coloring of ultra-thin products.

4. Ordinary blown color masterbatch:

It is used for blow moulding and coloring of general packing bags and woven bags.

5. Spinning masterbatch:

Used for textile fiber spinning dyeing, fine color masterbatch pigment particles, high concentration, strong dyeing power, good heat and light resistance.

6. Low color masterbatches:

It is used to manufacture low-grade products, such as garbage cans and low-grade containers, which do not require high color quality.

7. Special color masterbatch:

The color masterbatch is manufactured by using the same plastic as carrier according to the plastic varieties designated by users for products. For example, PP and ABS masterbatches are selected as carriers respectively.

Universal Master: A resin (usually PE with low melting point) is also used as a carrier, but it can be applied to coloring other resins besides the carrier resin.

8. General Color Master

General color masterbatch is relatively simple and convenient, but it has many shortcomings. Users are advised to choose special color masterbatch.

The heat-resistant grade of special color masterbatch is generally suitable for plastics used in products. It can be safely used at normal temperature. Only in the following circumstances will cause varying degrees of discoloration, one is that the temperature exceeds the normal range, the other is that the downtime is too long.

9. Matrix coloring has the following advantages compared with granulation coloring:

9.1. It is good for protecting the quality of plastic products to avoid the heating process caused by granulation and coloration when the coloring and product processing are completed at one time.

9.2. To simplify the production process of plastic products.

9.3. Can save a lot of electricity

4. Why use color masterbatches

The use of masterbatches has the following advantages:

1. Make the pigments have better dispersibility in the products:

Master colour is an aggregate made by uniformly loading supernormal amount of pigments into resins.

In order to improve the dispersibility and dyeing power of pigments, it is necessary to refine the pigments in the production process of masterbatch. The carrier of the special color masterbatch is the same as the plastic variety of the product, and it has good matching property. After heating and melting, the pigment granules can be well dispersed in the plastic product.

2. To maintain the chemical stability of pigments:

When pigments are used directly, water absorption and oxidation will occur when pigments are in direct contact with air during storage and use. When pigments are made into masterbatches, the quality of pigments can be kept constant for a long time because the resin carriers separate the pigments from air and water.

3. Guarantee the stability of product color:

The Color Masterbatch particles are similar to the resin particles, so they are more convenient and accurate in measurement. When mixed, they will not adhere to the container, and the mixture with the resin is more uniform. Therefore, the stability of the amount of additions can be guaranteed, thus ensuring the color stability of the products.

4. Protect the health of operators:

Pigments are usually powdery, easy to fly when added and mixed, and will affect the health of operators when inhaled by human body.

5. Keep the environment clean and free from contamination of utensils:

6. Simple process, easy color change, saving time and raw materials